Electric vs. Steam Heating in Beer Brewing

Breweries rely on effective methods to brew batches depending on the style and consistency the owner wants in the final product. The design of a brewery must be functional and accommodate the brewing equipment. The layout around the space has a big influence on productivity.

Electric and steam heating in beer brewing are two popular methods that deliver good results, but each has specific characteristics. These heating methods will directly impact the brewing process and the beer’s final taste, which is why you must align the method with your goals.

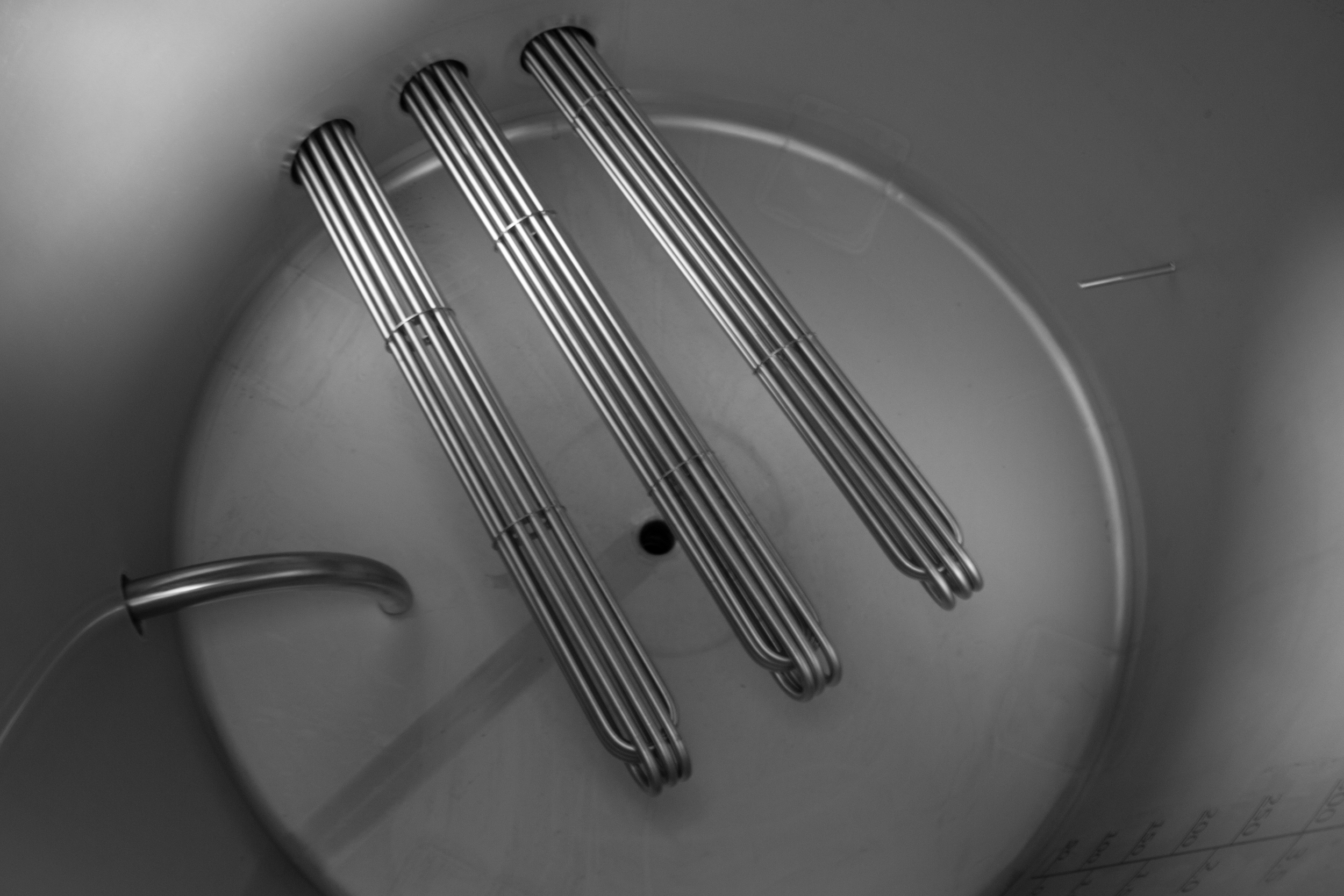

Electric Beer Brewing Process

This method requires certain steps in your brewery to work efficiently and consistently. The electric process consists of a large stainless steel tank with heating tubes that directly touch the water or wort, bringing the liquid to the desired temperature, which you can easily adjust.

The equipment for this brewing method requires an electrical connection of 208-480 volts, which is necessary for commercial use in small breweries. You might need to modify your space for better equipment management; this process usually takes longer and uses lots of energy.

Steam Heating Beer Process

This process is also popular during sterilization because it removes unwanted elements due to the high temperatures and allows ingredients to react with heat. Brewers require large amounts of steam with the help of modular boilers that regulate intensity and times to achieve complete and reliable results.

The heating process boils the wort with steam, sterilizing and stabilizing the beer. After this, a jacketed brite tank is a perfect option for storing and serving carbonated beer, especially in breweries with limited space, to optimize management and delivery.

Unique Process Characteristics

Each process has unique characteristics to help you decide which one suits your brewery the best. Some of the main pros and cons are as follows:

Electric Process Pros

The electric heat effectively transfers to the liquid.

An electric tank maintains a consistent temperature during the brewing process.

And the Cons

The electric process is long and will significantly increase your business’s electricity bill.

The machinery requires electrical service upgrades.

You might need to upgrade infrastructure for safety.

Steam Heater Pros

A steam heater provides a quick and reliable heating process.

Steam tanks heat efficiently with low expenses.

They are ideal for large-scale breweries.

And the Cons

Specialized machinery with higher costs.

Boilers must pass permits and inspections.

Depending on the size of your brewery and budget, choosing between electric versus steam heating for your brewing process will dictate the best option for your business.