DRY HOPPER / HOP DOSER

CraftMaster Stainless proudly offers the most innovative brewing equipment that helps brewers create even more delicious beer. The latest addition to our equipment inventory is the dry hopper, which is an excellent tool for maintaining your hops' crucial flavor and aromas during the dry hopping.

Also known as a hop doser, this instrument excluded oxygen from the hops by pressurizing the vessel with CO2 gas. By eliminating the oxygen, the hops can stay fresher longer and maintain their unique character, creating a beer bursting with aroma and flavor.

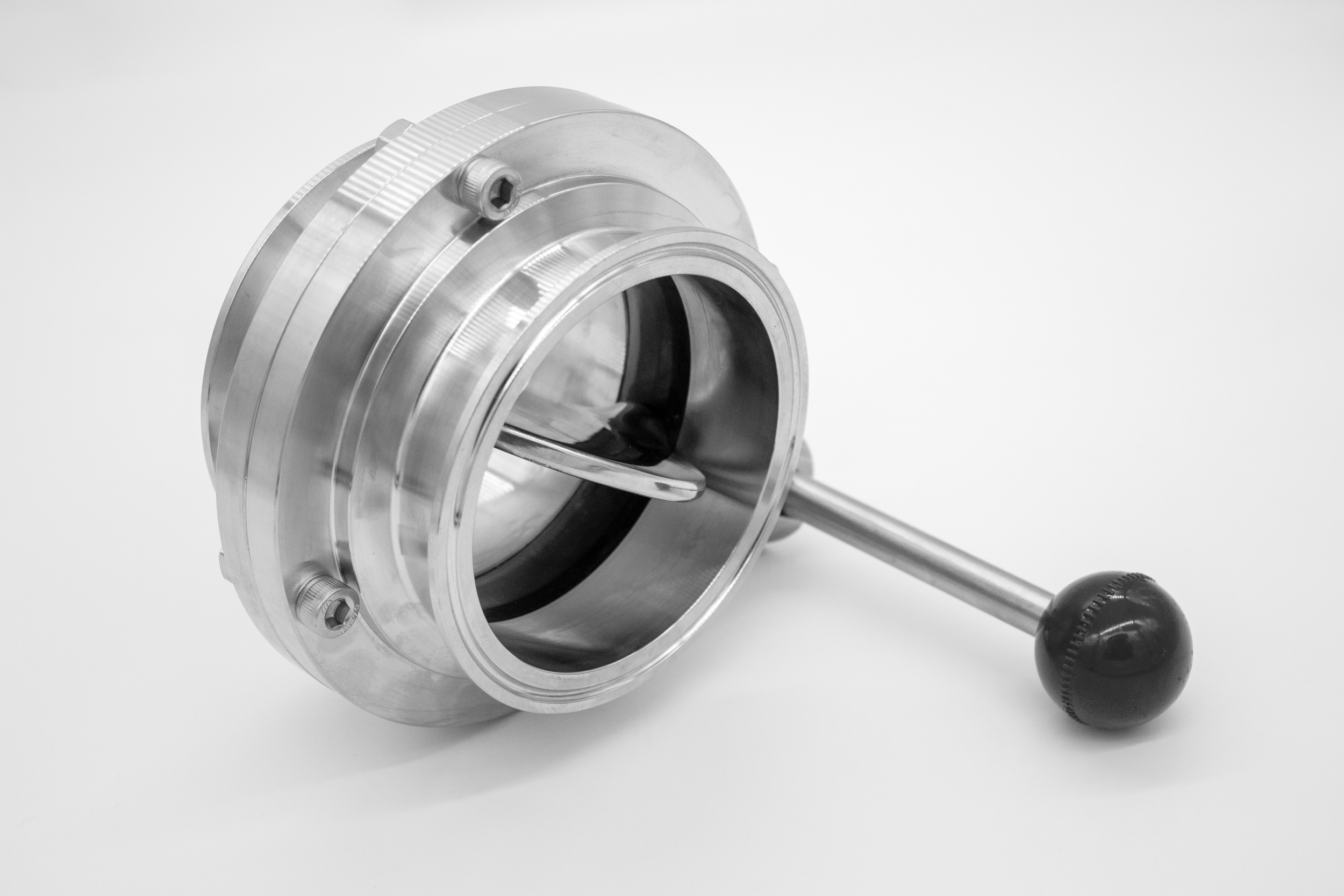

Once the oxygen is eliminated from the dry hopper, it drops the hops into the fermenter through a four-inch or six-inch butterfly valve attached to the hopping port for a fast and efficient dry hopping process.

Purchase a dry hopper for your brewery at CraftMaster Stainless, or contact our expert staff if you have any questions about the hop doser or any other brewing equipment in our inventory.

NOTE: We recommend purchasing extra 4” Butterfly Valves For the 3 Gal Hop Doser and 6” Butterfly Valves for the 5.8 Gal Hop Doser, so the Doser can be used for multiple vessels.

Key Features

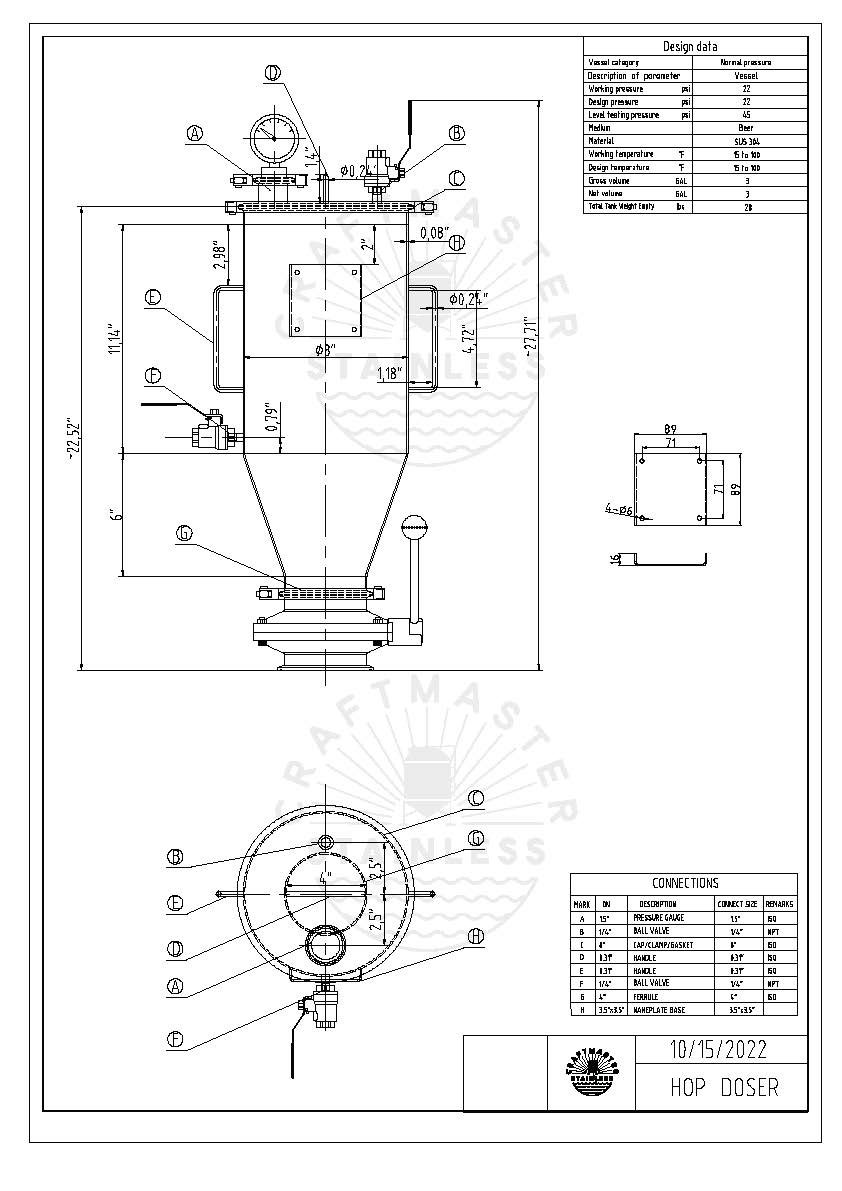

3 Gal Hop Doser

Interior/Exterior Tig Welded Stainless Steel

¼” CO2 Inlet Ball Valve

¼” CO2 Purge Ball Valve on lid

Pressure Gauge, 1.5” Tri-Clamp mount to top lid

Pressure Rating to 22 p.s.i.

4” Bottom port

4” Butterfly Shut-off Valve for bottom port

Handles on both sides for easy lifting

8” Top Opening with Cap and Handle

All Tri-Clamps and Gaskets included

Holds up to 15 Pounds of T-90 Hop Pellets

5.8 GAL HOP DOSER

Interior/Exterior Tig Welded Stainless Steel

¼” CO2 Inlet Ball Valve

¼” CO2 Purge Ball Valve on lid

Pressure Gauge, 1.5” Tri-Clamp mount to top lid

Pressure Rating to 22 p.s.i.

6” Bottom port

6” Butterfly Shut-off Valve for bottom port

Handles on both sides for easy lifting

10” Top Opening with Cap and Handle

All Tri-Clamps and Gaskets included

Holds up to 25 Pounds of T-90 Hop Pellets

Product Video

Advantages to using a Dry Hop Doser

Lower Dissolved Oxygen

Hands Free Funnel

Less chance of nucleation “Hop Volcano”

Keeps the flavor in the Hops

Where does the Dry Hop Doser Mount?

The hops are placed inside the Doser, then, clamp on top of your fermenter through the Dry Hopping Port with the 4” butterfly valve. We recommend you purchasing a second 4” Butterfly valve to leave installed on the tank.

Note: You must have a 4” Tri-Clamp style Hop Port located on top your tank vessel. 4” to 6” inch adaptors are available.

What Co2 Charging pressure should I fill my Dry Hop Doser to?

Before clamping your Hop Doser onto your Fermenter or Uni-Tank, you will want to check the pressure gauge on the vessel. The desired Charging Pressure on the Dry Hopper will be set slightly above what the current tank pressure is.

How do I connect and use the Dry Hop Doser?

Connect the Dry Hopper to the tank

Add hops to the Dry Hopper and close

Purge the hop Dry Hopper several times with CO2, to ensure oxygen is removed

Add pressure to the Dry Hopper so the psi is slightly above the pressure of the tank to be dosed

Open the 4” valve allowing the hops to be dumped into the tank

Close the valve to the tank and release the pressure in the Doser

This process can be repeated, if you require more than one hop load, for the brew

When taking off the Doser, ensure the valve to the tank is closed and there’s no pressure in the device.

Cad Drawings

Related Products

FOR MORE INFORMATION CALL

916-750-4677

Every Brewery is unique and requires different specifications. Please shoot us an email or give us a call for a quote.