Pro Line Beer Brewing Systems

SCROLL DOWN FOR PRICING AND SPECS

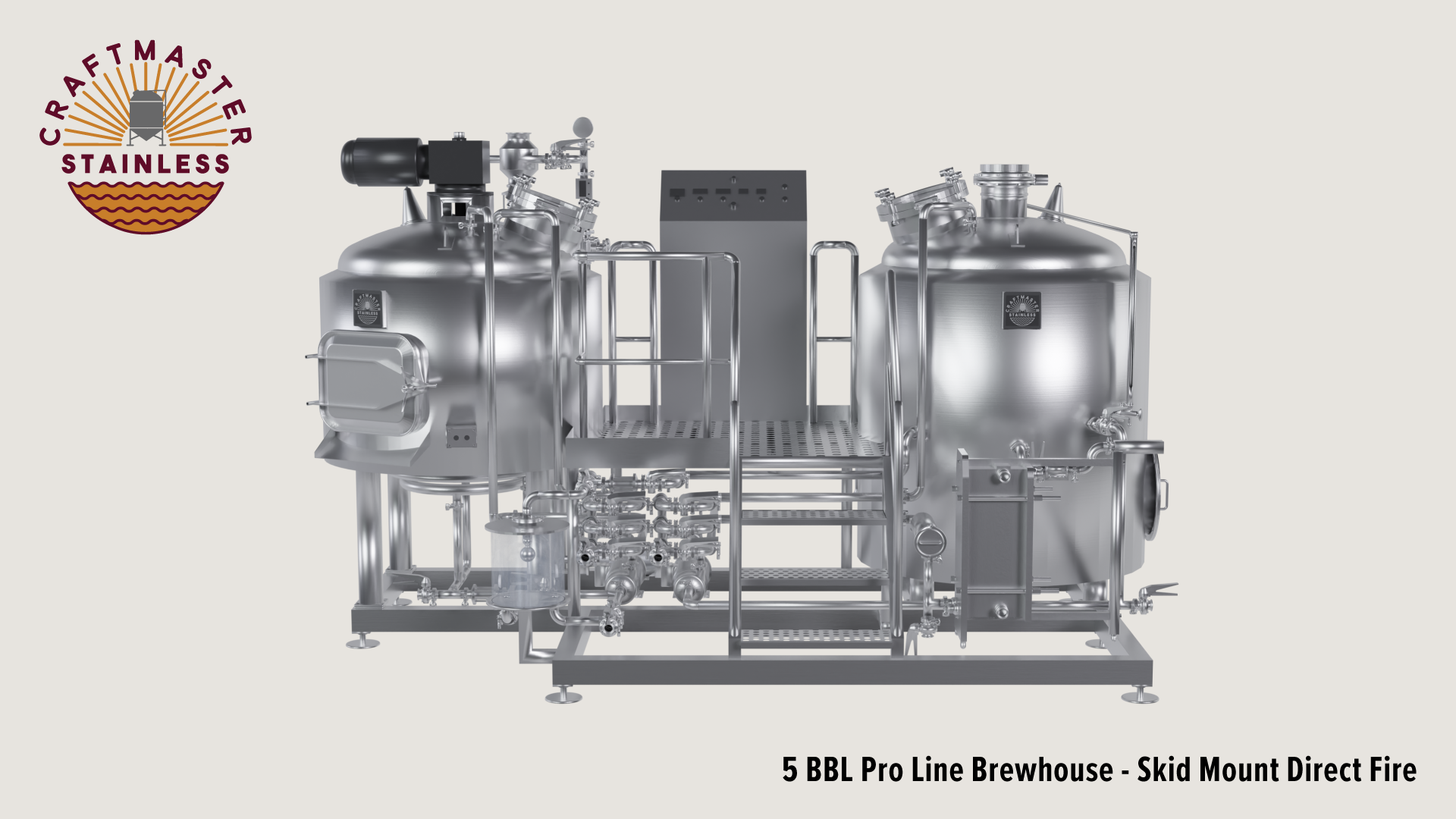

At CraftMaster Stainless, we want to create the ideal pro line beer brewing system for your brewery, regardless of its size. Our Pro Line brewhouse systems come in multiple sizes from 3.5 BBL to 10 BBL and bigger. Every brewery, big or small, deserves high-quality equipment, including our skid-mounted system for beer brewing.

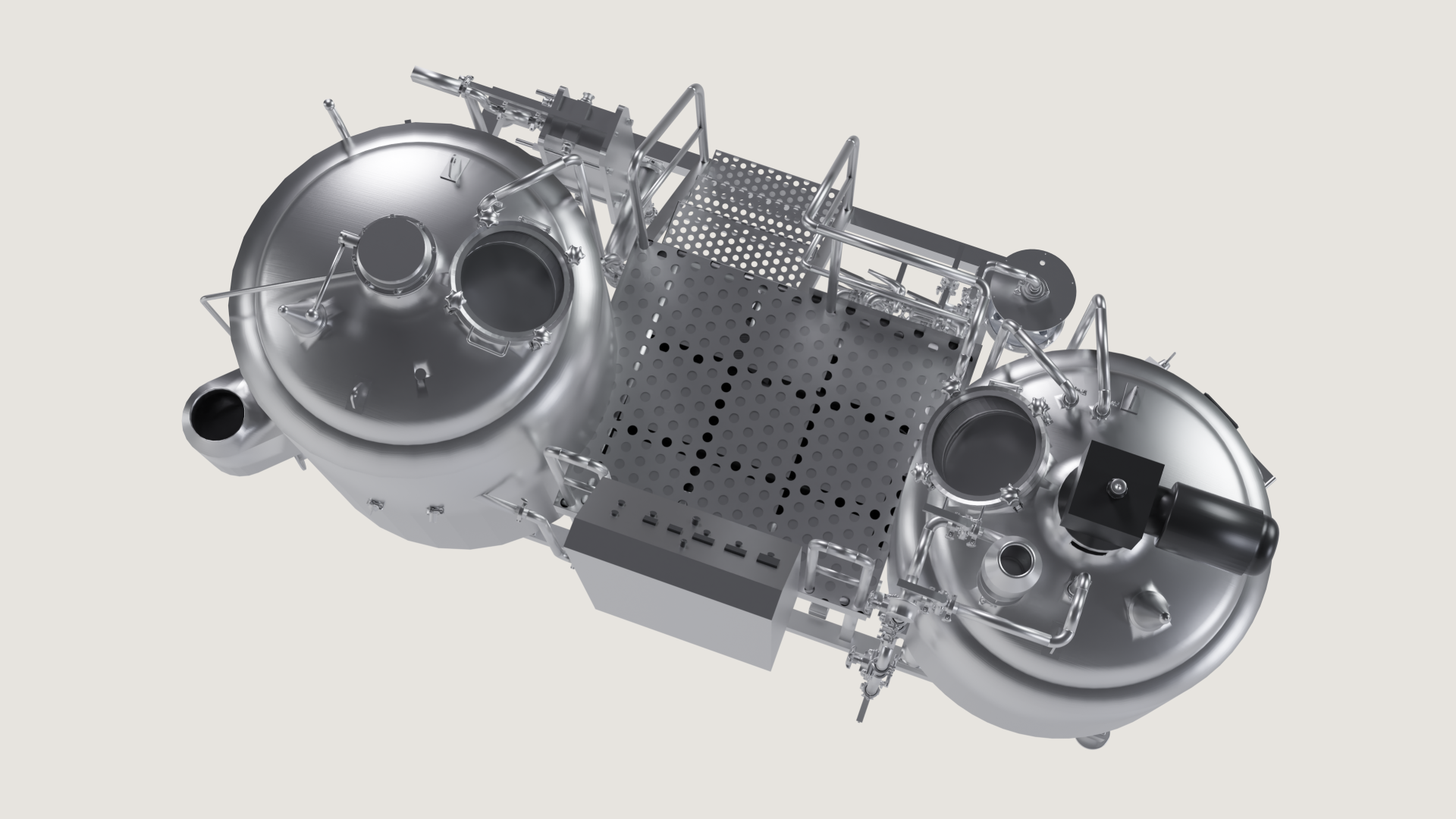

The Pro Line skid mount systems configuration comprises a centralized working platform between a combined Mash/Lauter vessel and a combined Kettle/Whirlpool. Technicians with years of experience in stainless steel fabrication and a passion for brewing craft our quality skid-mount pro brewing systems.

We offer skid mount systems with many options and can provide consulting for your expanding business or a new start-up business. If you’re ready to order a Pro Line beer brewing system for your establishment, get a quote for one below, or contact our staff if you have any questions.

Premium Build Quality

Strength, Quality, Value, just like our Pro Line 2-Vessel, only difference is the Giant Stainless Steel Frame skid that the Brewhouse is mounted to.

Strength… Heavy duty Platform frame, Dimple Die Deck, All brand named Components, Low Shear Pumps, Thick inner and external shell, 3” thick Insulated Jacketed, Huge Stainless Steel Skid frame, Full Washdown Pumps/ Motors

Quality… high grade 304 Stainless steel with all UL Certified electrical control components by Schneider Electric, Delta, and Omron. Also, items from other top manufactures like IFM, SEW, Bowpeller Pumps, and Midco Burners, High Quality precision Sanitary Tig welded joints, process piping all sanitary welded

Value... Building a cost-effective combined 2-Vessel Skid Mounted Brewhouse offering components from industry leading manufactures to create a simple brewing solution without compromising ease of control or brewing quality for our customers. The Skid mount is a fast and easy set-up operation for most Breweries. Skid mount will come pre-piped, all hardware included and all Brewhouse attributes will be mounted. Basically place, level, hook up your utility and/or steam connections, CIP and get to Brewing!

KEY FEATURES

Bowpeller Low Shear pump/motor, with variable speed control

Plate Heat exchanger

Wort Aeration System

LED Tank light assemblies

Grist hydrator

Plate Heat Exchanger,

Midco Burners, Direct fire Only

Sanitary Stainless Steel Valves, Fittings, Gaskets, Centralized valves, clamps all included

Combined Mash/ Lauter Tun

Combined Kettle/Whirlpool

Stainless Steel Dimple Die, Working Platform

Sink on Platform

Oversized Frame, Skid Mount

Glass Wort Grant

IFM Flow meters

Wort Strainer

System control cabinet, Semi-auto controls

Combined Kettle / Whirlpool Tank

Material: SS304 Stainless Steel

Steam, Direct Fire, and Electric available per your request

Inner Shell Thickness 3mm, Cladding Thickness 2mm

Inner Surface welds ground to Ra 0.6μm

Top fittings: 16” glass manway with Etched Engraved customer logo

2” 360 Degree Rotating CIP Ball

Large 8” Condensation stack

Condensation Trap

8” butterfly valve on condensation stack for making Kettle sours

LED Interior light

Side fittings: Thermowell, Graduated Sight tube, Chimney, Inspection Door on Direct Fire units,

Tangential whirlpool inlet

4” Burner Flange Mount (For Direct Fire Units only)

Bottom fittings: Wort draw-off, drain, Combustion chamber on Direct Fire units

COMBINED MASHTUN / LAUTER TUN FEATURES

Material: SS304 Stainless Steel

Steam Jacket Optional for Step Mashing

Inner Shell Thickness: 3mm, Cladding Thickness 2mm, Jacket Thickness 1.5mm

Inner Surface welds ground to Ra 0.6μm

Top fittings: 16” glass manway with Etched Engraved customer logo

2” 360 Degree Rotating CIP Ball

Sparge Ring

LED Interior light

2HP SEW Rake/Plow Motor with VFD control

Grist Hydrator and Sight Glass with Hot/Cold liquor blending

Side fittings: Thermowell, Spent Grain removal port

Bottom fittings: drain, Wort outlets, Wedge-wire false bottom, Wort collection header, Under flush Nozzles

BOWPELLER LOW SHEAR PUMPS

1.5”x1.5” Tri-Clamp

4.25” Impellar

External Seal for Easy Changeability

Silicon Carbide vs Carbon Rotating with Viton Elastomers

Standard Wash Down

2hp Stainless Steel Motor

3450 RPM

200-230V, Single or 3-Phase Available

Max Flow 130 GPM

Max Pressure 30psi

TDH 73’ (Total Dynamic Head)

Bowpeller Pumps made in Kenosha, WI, USA

WORKING PLATFORM

Temperature and pump controls have been positioned in optimal locations for ease of use.

Dimple Die deck for max grip

Wort Thief and Sample chiller tube

Sink on platform

SYSTEM CONTROL CABINET

Semi-Auto controls

Digital Omron Temperature control

Delta VFD Rake and Plow control

Delta VFD Mash Tun Pump control

Delta VFD Kettle Pump control