GAME CHANGER NANO BREWHOUSE SYSTEM

1 BBL INLINE

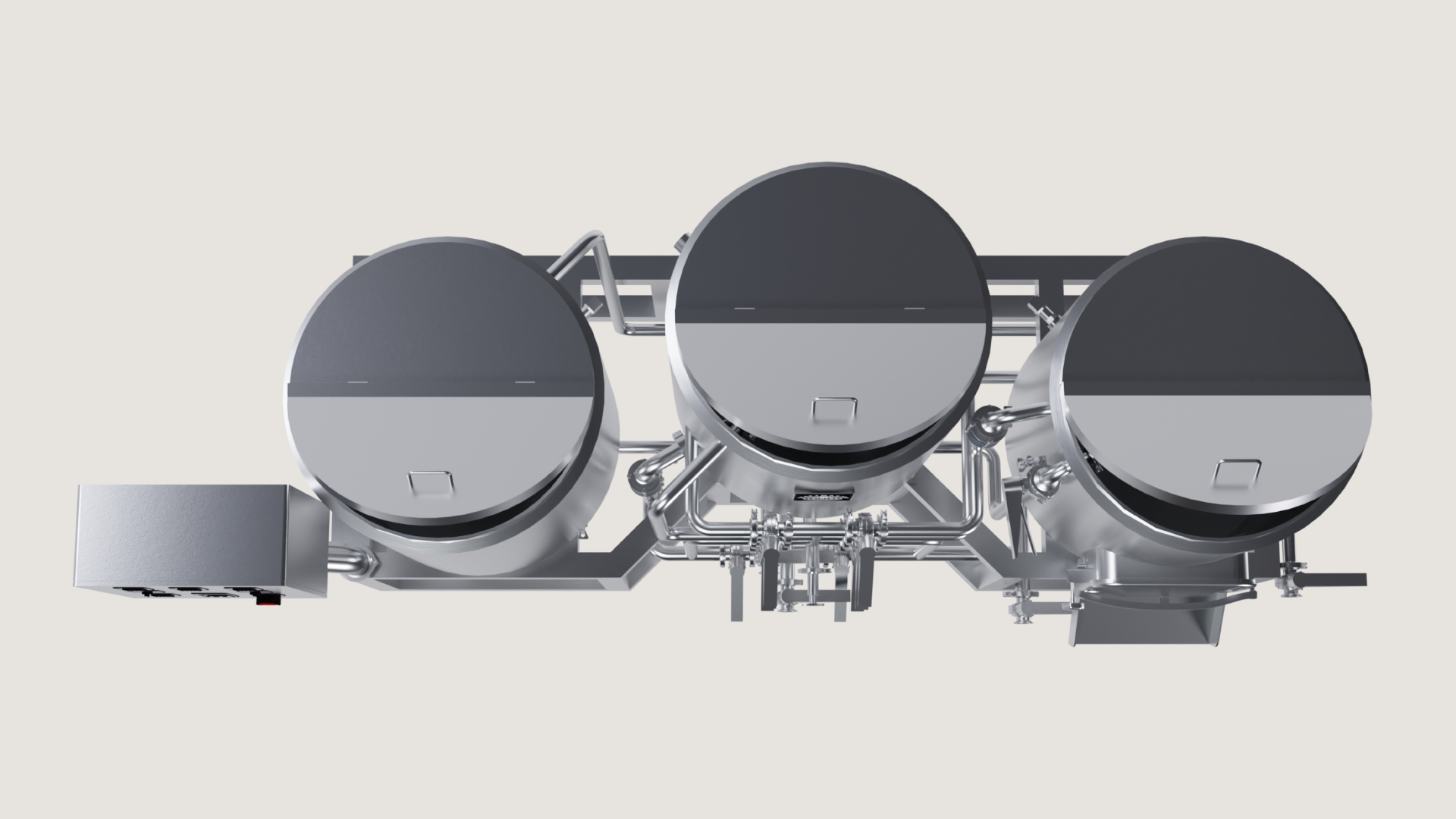

The 1BBL Game Changer Nano Brewhouse System by Craftmaster Stainless is built and designed with many of the same great features as our Pro Line Brewhouse Systems. The 3-Vessel Game Changer nano brewery system is ideal for the homebrew hobbyist, entry-level Micro Breweries, Pilot Brewing System, or full-scale Nano-Brewery production. If you are a larger scale Brewery the Game Changer system makes a perfect Pilot system for test batches letting you experiment and create many different recipes to keep your customers’ pallet satisfied!

KEY FEATURES

1BBL COMBINED MASH / LAUTER TUN

• Working Capacity: 1BBL Gross Capacity: 1.5BBL

• Wort Recirc/Vorlauf pipe with sight glass

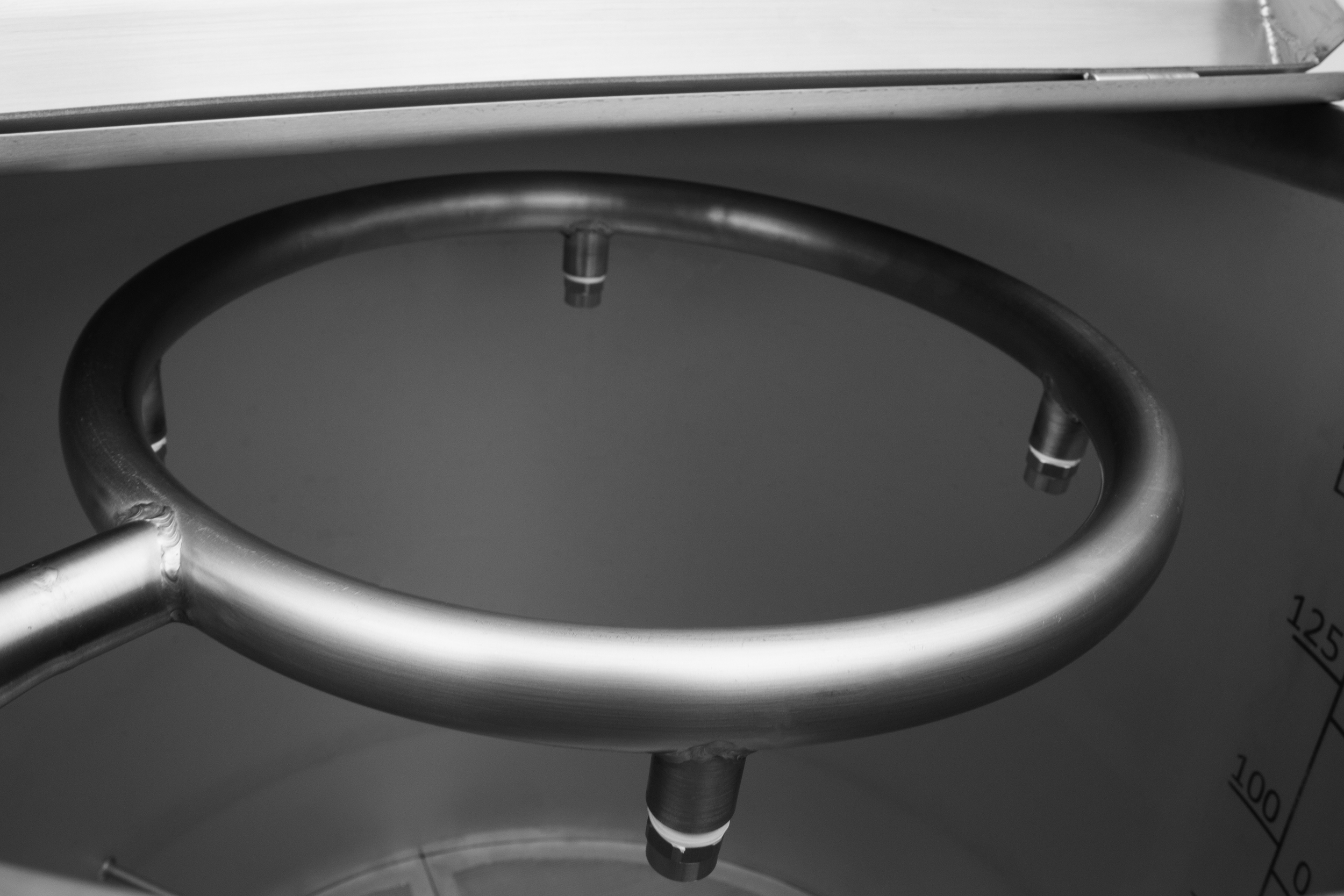

• Detachable sparge ring

• Graduation marks on inside wall of Mash Tun

• 360° Rotating Spray Ball to clean in place

• Removable False Bottom, 0.7mm milled gap

1BBL ELECTRIC COMBINED KETTLE / WHIRLPOOL TANK

• Working Capacity: 1BBL Gross Capacity: 1.75BBL

• Low level Sensor

• Bottom Drain outlet

• Tangential Whirlpool Inlet

• 1x Electric Heating Element

• 360 ° Rotating Spray Ball to clean in place

• Wort outlet with rotatable DIN fitting racking arm

• Graduation Markson inside wall of Kettle

1BBL HLT (HOT LIQUOR TANK)

• Gross Capacity: 1.5BBL

• 1x Electric Heating Element

• Low level Sensor

• Graduation marks on inside wall of HLT

SKID MOUNTED & PIPING

• All fittings, gaskets and valves are included

• 2x 1HP Centrifugal Brewhouse Pumps

• HLT Pump Controlled by VFD

• Mash/Kettle Pump Controlled by VFD

• CONTROL CABINET

• PID Temperature Controllers, PT100 RTD for each vessel

• Centralized Piping and Valve Manifold

• On/Off switches for electric heating elements

• On/Off switches for motors with VFDs

• Emergency Stop Switch

• CE, ISO, UL Certified Components

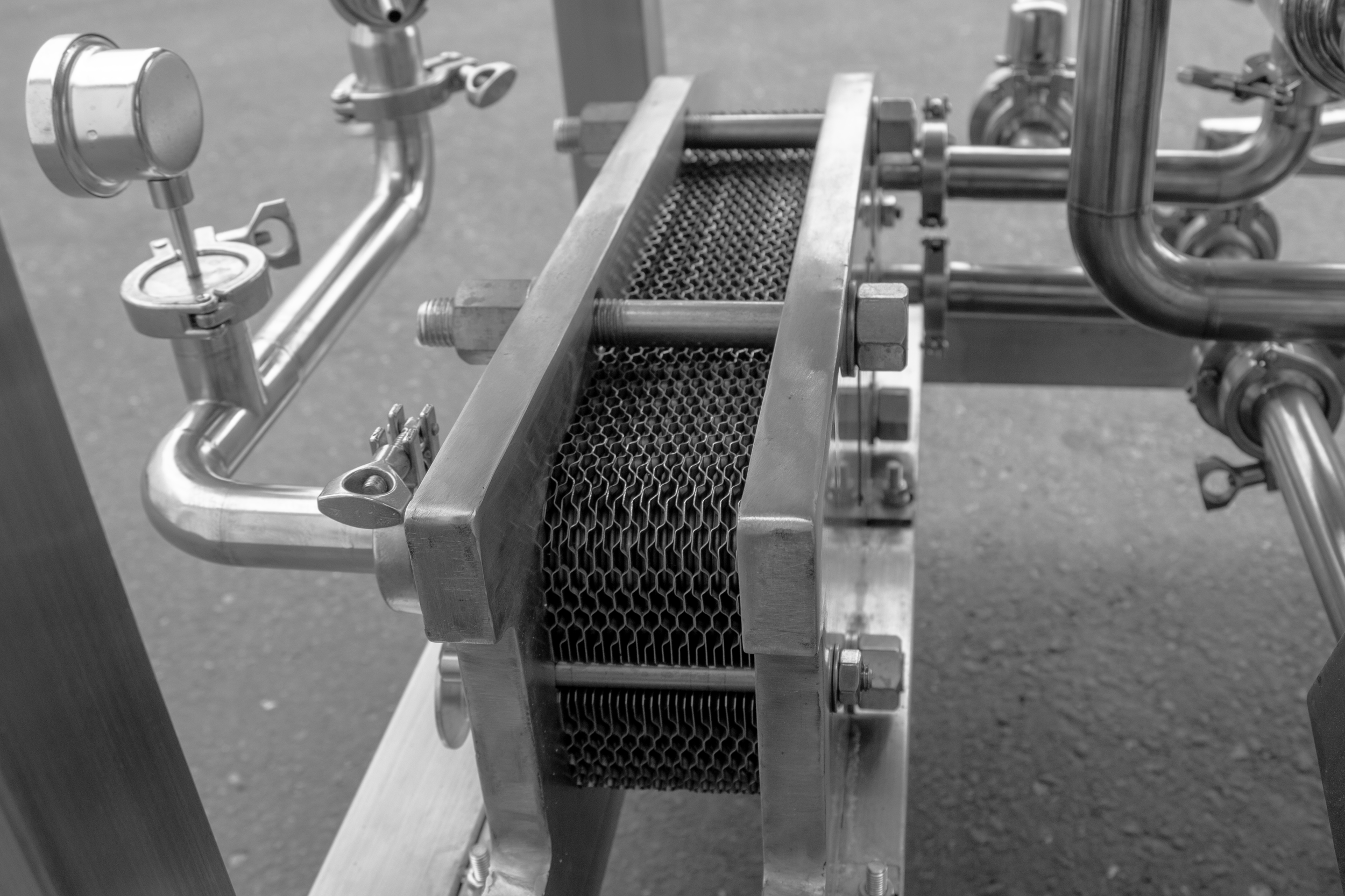

Plate Heat Exchanger, 1BBL, 1m2

• Working Capacity: 1m2, Single Stage Heat Exchanger

• Design Pressure: 145psi

• Design Temperature: 300F

• Hop /Strainer mounted before PHE

• Temperature Gauge after PHE

• Sight Glass mounted after PHE

• Wort aeration stone mounted in line with sight glass and temperature gauge

OPTIONAL UPGRADES

3.5 KW RIMS HEATING ELEMENT

RIMS stands for Recirculating Infusion Mash System. It continuously pulls mash wort out of the mash tun, pumps it through the tube where an electrical heating element is installed resulting in better mash temperature stability.

CONDENSER STACK

Our condenser stacks will keep steam from condensing and dripping back into the kettle. Instead, the stack allows steam to vent out and collect down towards a floor drain.